In the field of stem cell process engineering it is very important to create controlled environmental conditions for the cell growth. This requires, among other things, the use of three-dimensional (3D) structural elements on various size scales, starting from nano-structured cell niches, right up to complete reactor systems in the liter range with (micro-) fluidic supply systems. The use of various digital production techniques for this purpose allows the rapid production and testing of prototypes.

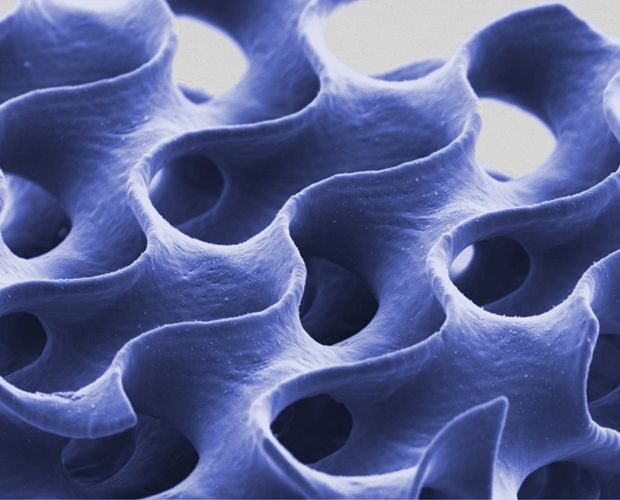

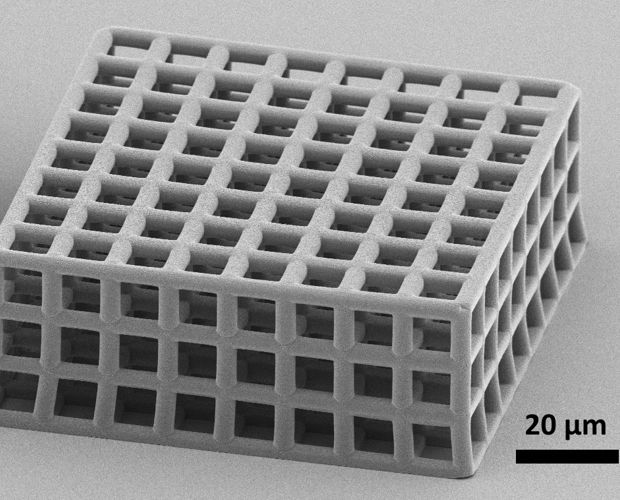

The Project Center for Stem Cell Process Engineering has a broad range of different 3D printing technologies for the implementation of product ideas. The offer ranges from the classical FDM printer with thermoplastic print materials, to modern commercial DLP-based UV printing systems, right up to especially developed 2-photon polymerization laser structuring systems with which the tiniest freely designable 3D structures can be realized in the 100 nm resolution range. Printing with biologically based inks is also possible with the available bioprinters. Modern 3D design tools and tailor-made material development allow a holistic process development, from the design to the adjustment and adaptation of the material properties and processing parameters, right up to the finished prototype.

Key technologies in this area are:

- Filament printing

- UV-DLP printing of polymers and composite systems

- Free-form 3D 2-photon polymerization structuring

- Extruder printing of bio-inks with living cells as well as of pure scaffold structures

Fraunhofer Project Center for Stem Cell Process Engineering

Fraunhofer Project Center for Stem Cell Process Engineering