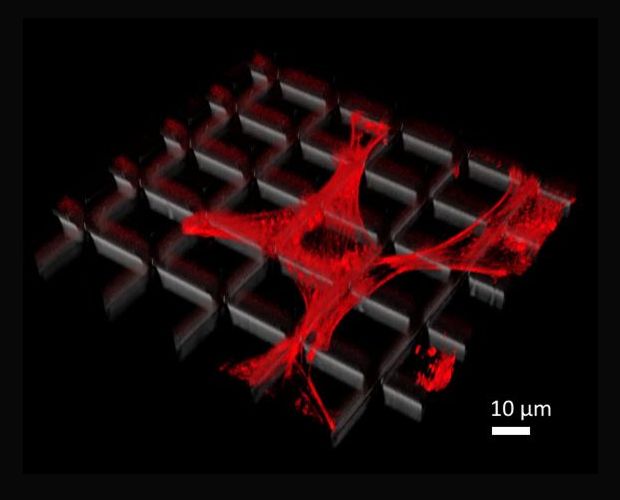

Today's gold standard in human cell cultivation is still limited to 2D culture dishes, usually of polystyrene and with adhesion-promoting biocoatings. Within this 2D culture, the behavior of the cells is analyzed and a wide range of environmental stimuli is tested. It has been proven, however, that cells behave in a completely different way in their native, physiological, 3D environment within the extracellular matrix and in contact with the surrounding cells, and respond differently to the 2D culture to external stimuli or pharmacological active substances. The constant intercellular exchange of biochemical and biophysical signals influences the cell behavior and fundamentally alters cell properties such as morphology, proliferation rates and differentiation. These differences are essential for the expansion of stem cells, and all the more important for further differentiation processes, which is why innovative 3D environments are being designed and developed to imitate physiological conditions.

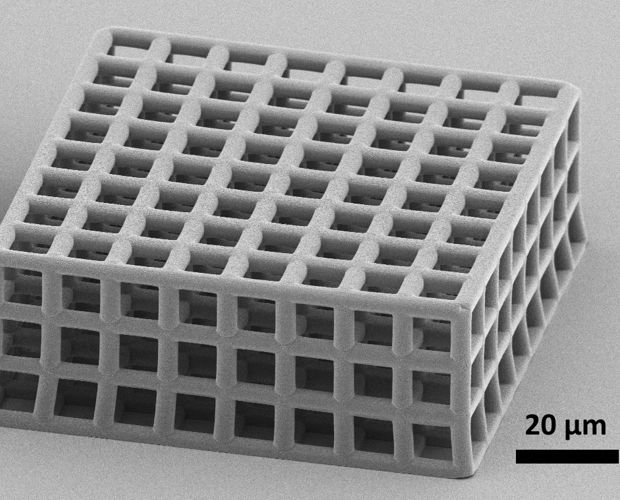

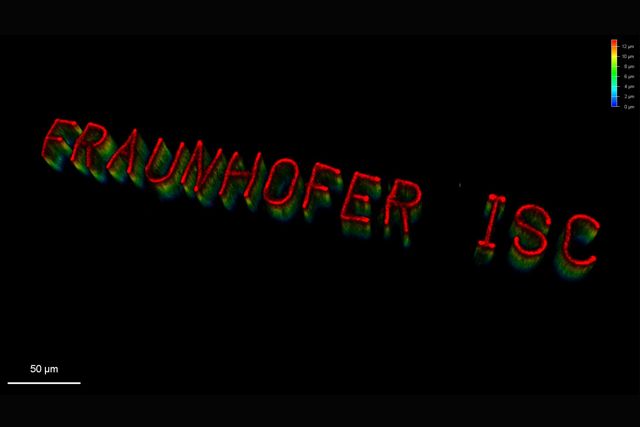

The working group 3D Designer Materials is collaborating closely with the working groups Optics-Electronics and Dental of the Fraunhofer ISC on the development and optimization of materials for 3D cell cultivation and its structuring. A wide range of base materials are used here, which can be adapted accordingly to the application and the cell type. These adjustable properties include, for example, the Young's modulus, various surface functionalizations, the surface energy and roughness, as well as the biodegradability. Composites of various materials are used to extend the property profiles. The materials are structured using a wide range of methods in quasi-3D (2.5D) and 3D. The spectrum ranges from 3D print, micro- and nanoimprint, two-photon polymerization right up to classical lithography.

Priorities

- Development of 3D-structurable materials for cell cultivation/medical engineering

- Material optimization to suit requirements profile and cell type

- 3D design and 3D structuring

- Broad parameter spectrum for Young's modulus, functionalization, surface roughness

- Modern material characterization

Fraunhofer Project Center for Stem Cell Process Engineering

Fraunhofer Project Center for Stem Cell Process Engineering