Supplying research and development labs in the field of regenerative medicine and biological sciences with induced pluripotent stem cells (iPSC) in the necessary high quality demands advanced automated processes. Essential part of this process are dynamic, fluidic systems for cell supply in cultivation and a later cell differentiation. These steps require high demands on the constant, homogenous supply of the cells under defined conditions. At the same time, influences on the cellular behavior by dynamic effects are highly undesirable so that shear forces have to be minimized.

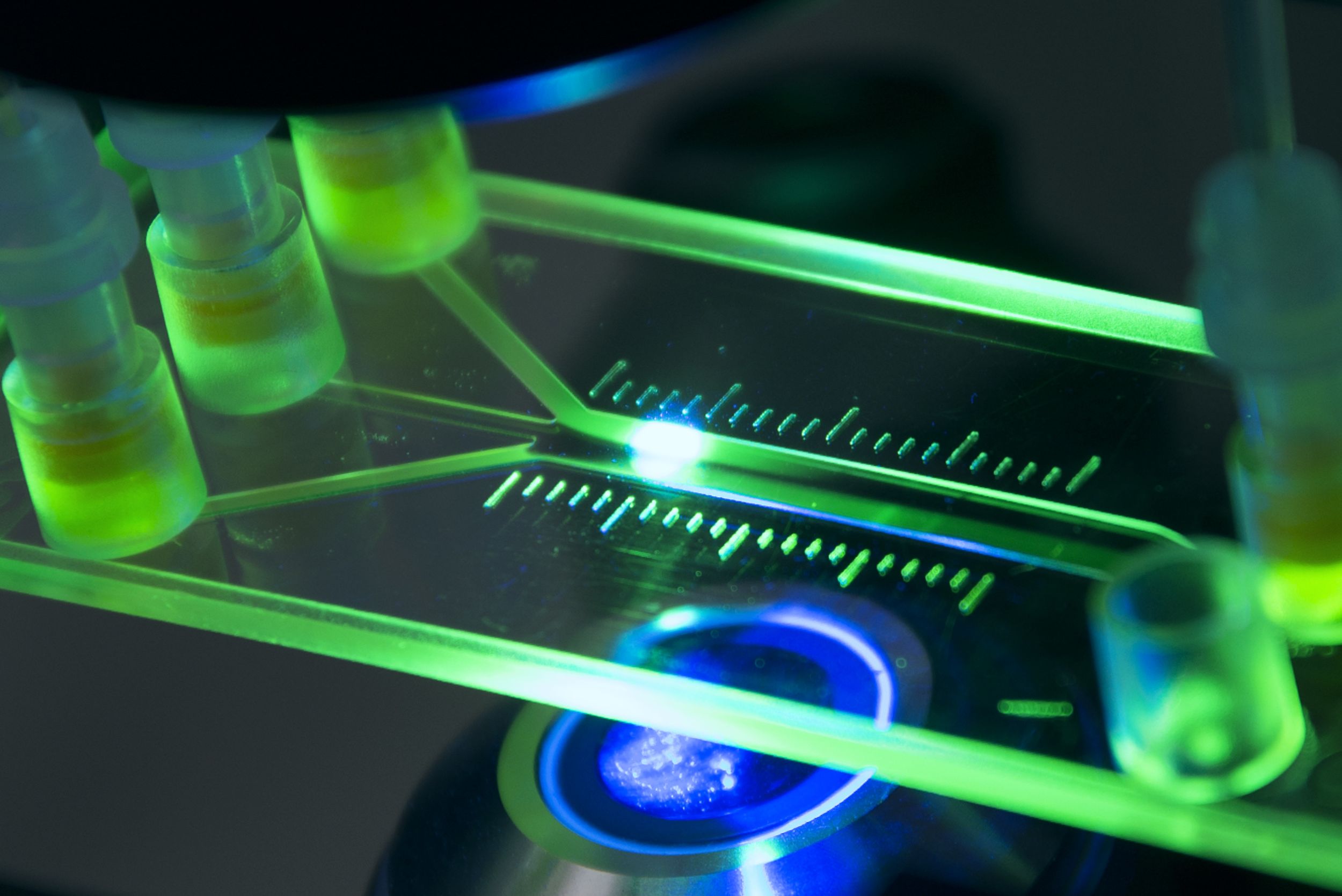

In addition to fluidic systems for cell culture, the development and design of innovative on-chip devices for medical and pharmaceutical engineering are part of this work group. Here, microfluidic systems allow for the manipulation and separation of cells as well as the targeted influencing of cells and cell ensembles by chemical gradients which can be controlled with high spatio-temporal precision. Another microfluidic approach allows for the localized variation of chemical environments to spatially vary the composition or topography of a cell environment in the production of scaffolds. All development processes of microfluidic systems are supported by finite-element simulations, allowing for cost-saving designs and customer-oriented developments tailored specifically for the respective application.

Priorities

- Automated, dynamic cell supply for the expansion and differentiation of stem cells

- Development and design of on-chip devices

- Optimization of customer-specific processes in bioreactors and on-chip devices

Fraunhofer Project Center for Stem Cell Process Engineering

Fraunhofer Project Center for Stem Cell Process Engineering