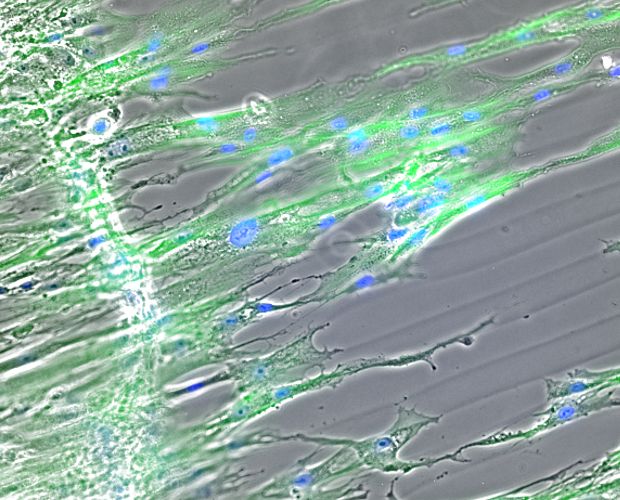

The need for optimized growth surfaces for stem cells is becoming increasingly important both in the field of bioprocess engineering as well as in tissue engineering. In bioprocess engineering, surfaces are required for in-vitro work sequences that can better represent the physical and chemical boundary layer of the native environment, and thus exercise a decisive influence on the quality of the stem cells. The boundary layer and its characteristics are thus vitally important for the cell interaction and thus also for the 'fate' of the stem cell.

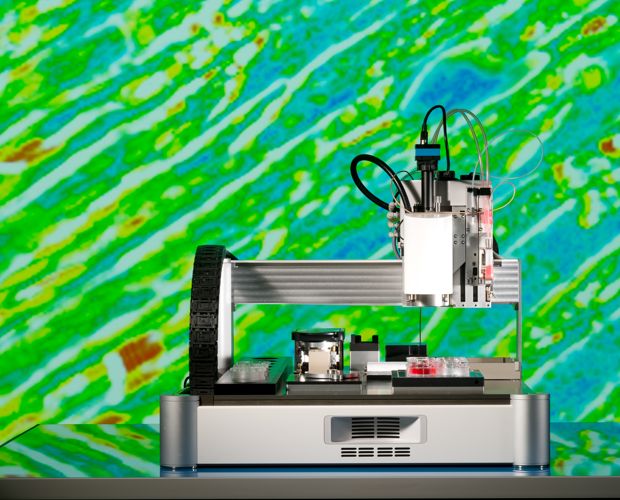

Boundary layers such as, for example, biomimetic growth surface of so-called microcarriers with a high surface-to-volume ratio, allow an efficient expansion of the stem cells for applications with high cell requirements. Bioprinting, for example, is one of the applications with a high cell requirement which will play an increasingly important role in future approaches in tissue engineering. Here also, formulations of biomaterials and proteins are combined as bio-inks with stem cells to produce the 3D model in the printing process.

The working group Stem Cell Materials focuses on the biotechnological preparation, modification and structuring of biomaterials with a special focus on alginate-based hydrogels. Properties are selectively modified (bonding of adhesion molecules) or additionally introduced (e.g. increase of conductivity) in order to achieve the optimum cell-material interaction.

Priorities

- Enhancement of biomaterials (chemical and physical modification)

- Innovative cultivation systems for stem cells (bioreactors, bag-based systems)

- Bio-inks for additive production (printable formulations of tissue-specific bio-inks)

- Analysis of the cellular behavior on biomaterials

- Material analysis (mechanical and chemical characterization)

Fraunhofer Project Center for Stem Cell Process Engineering

Fraunhofer Project Center for Stem Cell Process Engineering